Prototype machining is central to product development, enabling businesses to design, test, and refine parts quickly. In Minneapolis, advanced technologies are transforming this process, enabling faster turnaround times, greater accuracy, and improved efficiency across various industries. The city’s strong manufacturing base, combined with new digital tools, makes it a hub for high-quality prototyping.

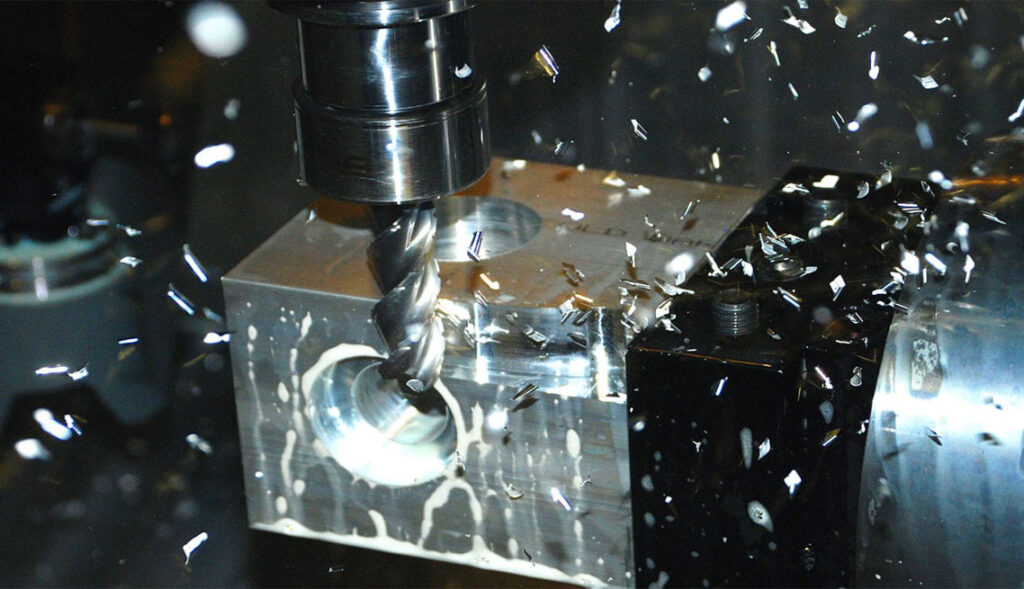

The Role of CNC Machining

Computer Numerical Control (CNC) machining remains the backbone of modern prototyping. By using software-driven instructions, CNC machines deliver precise cuts and consistent results. Manufacturers in Minneapolis depend on this reliability to minimise errors and ensure that prototypes closely match digital designs before moving into large-scale production. CNC technology continues to evolve, offering faster setups and better integration with design software.

Additive Manufacturing and 3D Printing

Additive manufacturing has changed the way prototypes are created. Instead of lengthy production cycles, 3D printing enables experimentation and adjustments at a rapid pace. The significant benefits include:

- Faster design iterations without high costs.

- Ability to produce complex and detailed parts.

- Lower material waste compared to traditional methods.

When paired with CNC machining, 3D printing makes Minneapolis prototype machining more flexible and effective, supporting industries with demanding timelines. Together, these processes reduce risk while enhancing innovation.

Advanced Materials in Prototyping

The choice of materials has a significant impact on how prototypes perform. Today, companies use a variety of advanced options, such as:

- Polymers for lightweight flexibility.

- Composites for added strength and durability.

- Alloys for resistance to wear and long-term testing.

These materials allow prototypes to be tested under real-world conditions, ensuring they meet practical requirements before final production. With better materials available, engineers can also explore more creative designs while maintaining durability.

AI and Automation in Machining

Artificial Intelligence (AI) and automation are improving speed and reliability in machining. Their applications include:

- Predicting tool wear to prevent downtime.

- Optimising cutting speeds for higher efficiency.

- Running automated systems with minimal supervision.

By using these advancements, Minneapolis prototype machining firms can complete projects more quickly while maintaining accuracy. Automation also helps shops handle higher workloads without compromising quality.

Digital Twin Technology

Digital twin technology has revolutionised the testing and evaluation of prototypes. Instead of relying only on physical versions, engineers can now simulate performance digitally. This approach is helpful for:

- Assessing parts under different stress conditions.

- Reducing the need for repeated physical testing.

- Forecasting performance before scaling production.

Such simulations save both time and resources, creating a more efficient path to final product development.

Cloud-Based Collaboration

Collaboration is key to successful prototyping. Cloud-based platforms make the process smoother with features like:

- Real-time file sharing and updates.

- Easier coordination among different teams.

- Faster decision-making through shared access.

These tools ensure that designers, engineers, and clients stay aligned throughout the development process. As a result, projects progress with fewer delays and improved communication.

Sustainability in Machining

Sustainability has become an essential factor in machining practices. Many companies in Minneapolis now adopt methods such as:

- Using energy-efficient equipment.

- Recycling leftover materials.

- Reducing production waste.

These practices lower costs while also reducing the environmental impact of manufacturing. By combining advanced technology with sustainable methods, prototype machining supports both efficiency and responsibility.

Conclusion

Prototype machining in Minneapolis is advancing through the use of CNC systems, 3D printing, advanced materials, AI, and digital solutions. These innovations are helping businesses achieve faster, more accurate, and more sustainable outcomes, ensuring prototypes are ready for testing and production with greater confidence.